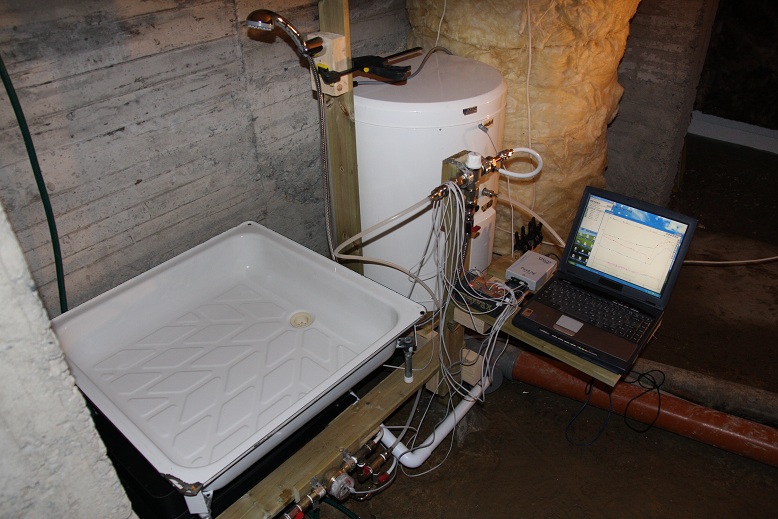

To verify the performance of the first prototypes of our DWHR product, we built a test setup in the basement of Arthur’s house. Its main components are an electric hot water tank, a shower platform and a PC based multi-channel logging tool. The heat exchanger unit is placed directly under the shower platform and connected with 40mm PP pipes and elbows for the drain as well as 1/2″ fittings and PEX tubes for the cold water. An adjustable thermostatic valve mixes the flow from the warm water tank and the cold water to the required shower water temperature. A set of valves controls the water flow, and can be set to both an unbalanced configuration (preheated water from the DWHR unit only goes to the thermostatic valve) and balanced situation (preheated water goes to both hot water tank and thermostatic valve). Temperature sensors are built in to measure the cold- and drain-water temperatures at the respective in- and out-lets. In addition we are using a flow meter to log the shower flow rate.