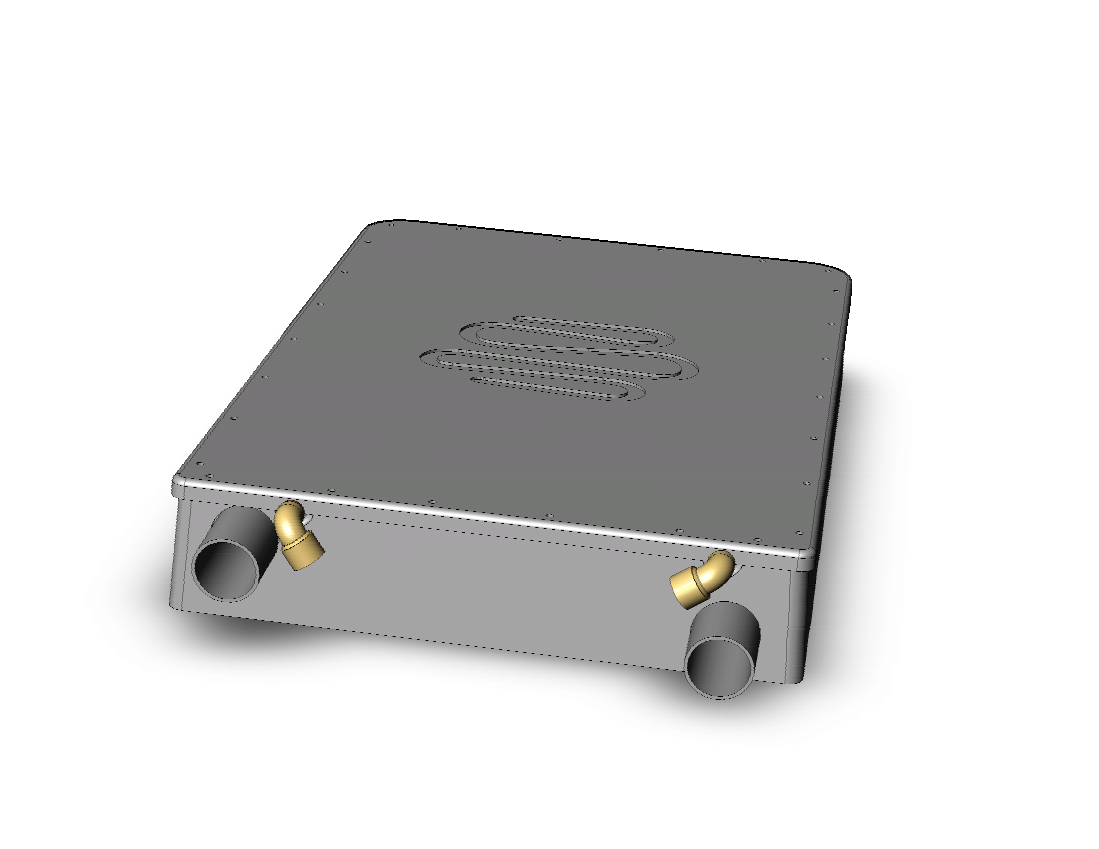

The 3D model is now refined as far as we can before actually making the product. It consists of two main parts: a plastic enclosure and a copper pipe unit.

The Norwegian company Ny Plast will be making the mold and do the actual vacuum forming for the meandering canal structure where the drain water will flow. It turns out that the design literally is stretching the limits of this low cost production method. The usual maximum stretch of the plastic sheet of 3x is pushed to 4x. Prior to start up they are now making a small test to see if this is possible. Two parts are needed to do this. The normal vacuum mold and in addition a «piston» mold that will push the plastic down into the canals and help the vacuum to form the part. Do hope this will work out.

The pipes will be manufactured in China. We are very pleased that we have found a company that has been given us useful advice during the design process. The pipes are now designed to be bent in their mainstream HVAC production line. This will contribute to predictable cost, consistent quality and flexible volume ramp up.